ROLLER REVERSE V.P.DRIVEN

16.99 USD ($)

Product Details:

- Noise Level <75 dB

- Capacity Up to 2 Ton/hr

- Surface Finish Painted / Smooth

- Size Standard / Customizable

- Motor Power 5 HP Induction Motor

- Lubricating System Manual/Automatic

- Drive Type V-Belt Driven

- Click to View more

X

ROLLER REVERSE V.P.DRIVEN Price And Quantity

- 50 Piece

- 16.00 - 17.00 USD ($)

- 16.99 USD ($)

ROLLER REVERSE V.P.DRIVEN Product Specifications

- Approx. 300 kg

- <75 dB

- Blue / Grey

- Heavy-duty construction, Robust design, Low maintenance

- Up to 2 Ton/hr

- Mild Steel (MS)

- 5 HP

- Industrial Conveyor, Reverse Roller Applications

- Painted / Smooth

- Standard Atmospheric

- Standard / Customizable

- Electric

- 1600 x 800 x 1200 mm

- 5 HP Induction Motor

- Roller Diameter: 80-120 mm

- Manual/Automatic

- 220-440 V

- V.P. Driven Reverse Mechanism

- Rectangular Base with Cylindrical Rollers

- Powder Coated

- ROLLER REVERSE V.P. DRIVEN

- V-Belt Driven

ROLLER REVERSE V.P.DRIVEN Trade Information

- Nhava sheva

- Telegraphic Transfer (T/T)

- 100000 Piece Per Week

- 2 - 4 Days

- Free samples available with shipping and taxes paid by the buyer

- Australia, Central America, Western Europe, North America, Middle East, South America, Asia, Eastern Europe, Africa

- All India

Product Description

Details

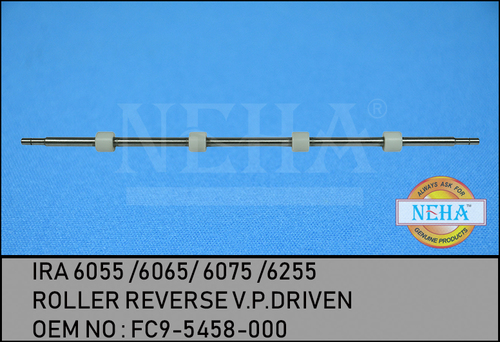

- Model Number : IRA 6055 /6065/ 6075 /6255

- Product Name : ROLLER REVERSE V.P.DRIVEN

- Oem No : FC9-5458-000

- Long lasting good quality

- Excellent result all the time

- Reasonable price

Customizable Performance for Industrial Needs

With options for roller material (mild steel or stainless steel), customizable roller numbers, lengths, and diameters, the ROLLER REVERSE V.P.DRIVEN can be tailored to specific conveyor and reverse roller requirements. Its heavy-duty construction and robust design make it ideal for industrial operations handling up to 2 tons per hour.

Advanced Safety and Efficiency

Safety and efficiency are prioritized with integrated thermal protection, corrosion-resistant surfaces, and a noise level under 75 dB. The inclusion of manual or automatic lubrication systems, alongside a user-friendly electric power source, ensures smooth and reliable operation for continuous industrial applications.

Versatility and Low Maintenance

This conveyor accommodates various mounting settings with its floor-mounted design, painted or smooth surface options, and a standard or customizable color palette of blue and grey. Its V.P. driven reverse technology and low-maintenance requirements offer practical benefits for manufacturers, exporters, and suppliers across India.

FAQs of ROLLER REVERSE V.P.DRIVEN:

Q: How does the V.P. driven reverse mechanism work in this roller conveyor?

A: The V.P. driven reverse mechanism allows the rollers to change direction automatically or semi-automatically, depending on the model. This functionality is essential for applications where product direction needs to be reversed without manual handling, improving workflow efficiency.Q: What industries can benefit from using the ROLLER REVERSE V.P.DRIVEN conveyor?

A: Industries such as manufacturing, warehousing, logistics, packaging, and distribution can benefit from this conveyors robust design and versatile features. It is particularly suited for environments requiring reliable material handling and reverse roller applications.Q: When should I opt for stainless steel rollers instead of mild steel?

A: Stainless steel rollers are recommended for environments with high moisture, chemical exposure, or stringent hygiene standards, as they offer superior corrosion resistance. Mild steel is suitable for dry, non-corrosive conditions and general-purpose industrial applications.Q: Where should the ROLLER REVERSE V.P.DRIVEN system be installed for optimal performance?

A: The unit is designed for floor-mounted installation in industrial facilities. Ensure the location provides enough space for the conveyors dimensions (1600 x 800 x 1200 mm) and allows easy access for maintenance, operation, and integration into existing conveyor systems.Q: What is the recommended process for maintaining this conveyor system?

A: Regular lubrication using the built-in manual or automatic system is advised. Additionally, inspect rollers, belts, and the power system periodically for wear and tear. Cleaning and surface checks preserve the powder-coated finish and extend operational lifespan.Q: How is thermal protection incorporated into this conveyor, and what are its benefits?

A: The ROLLER REVERSE V.P.DRIVEN is equipped with integrated thermal protection to safeguard the motor and electrical components against overheating. This feature reduces the risk of breakdowns, ensuring safe and uninterrupted operation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS